BRADLEY PARK

Bradley Park is a small layout, 8ft x 2ft (not including the fiddle yard), depicting a set of rail served industries. The idea was to make the layout as nondescript as possible as far as time and region are concerned so we can run as wide a range of stock as possible.

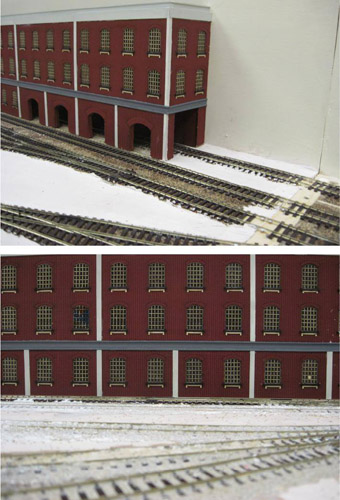

The buildings have been designed to be as generic as possible so are all made from brick because any stone buildings would place the layout in a certain locale.

Bradley Park has been named in memory of Paul Bradley, one of our club’s long standing members. We are very pleased his family let us honour him in this way.

The layout was also started to help promote the club and encourage new members to join and learn new skills. It has been very successful and we have several new members who have learnt how to lay track, solder, wire up switches and develop scenery techniques.

Some experienced members have scratch built buildings, either from plasticard or laser cut from thin mdf.

Bradley Park is available for operation on club nights and it has also been exhibited.

Great to see Bradley Park completed and running for members to operate their own stock. |

|

|

Suitable for stock from lots of eras. |

Layout boards erected, minus the fiddle yard. 8ft x 2ft. |

|

|

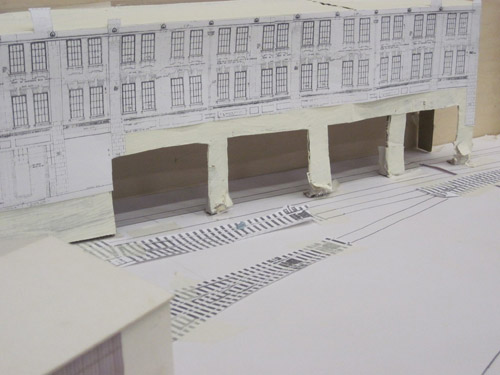

The track plan was drawn on to a roll of paper and building mock ups were made from cardboard boxes to get an idea of size. |

Cardboard warehouse box. |

|

|

Cork underlay was stuck down for the track bed and heavy lead weights used to keep it in situ. |

Track was stuck down with pva adhesive. Rails were attached to either small brass screws or copper clad sleepers at baseboard joints and then cut with an Exacto saw. |

|

|

Part of the Bradley Park workgroup busy wiring underneath the baseboards for both analogue and DCC operation. |

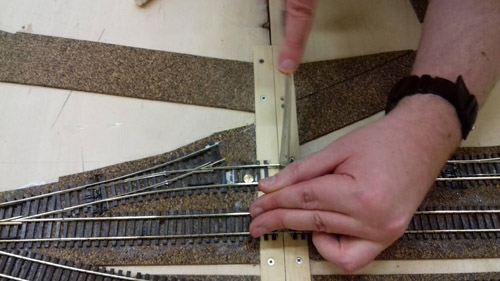

The three way point was hand made and it allows the top road to be isolated, leaving just the bottom two roads switchable. |

|

|

A small group of club members discussing how to assemble a hand built turnout. |

Printed mockup of one warehouse along the back scenic break. |

|

|

The laser cut warehouse in situ. |